Bengal: Mines and minerals, c. A.D. 1900

This article has been extracted from THE IMPERIAL GAZETTEER OF INDIA , 1908. OXFORD, AT THE CLARENDON PRESS. |

Note: National, provincial and district boundaries have changed considerably since 1908. Typically, old states, ‘divisions’ and districts have been broken into smaller units, and many tahsils upgraded to districts. Some units have since been renamed. Therefore, this article is being posted mainly for its historical value.

Mines and minerals

Coal is the chief mining industry. The Bengal mines furnish more than 83 per cent, of the total output of coal in India, and nearly the whole of the coke. With the exception of a narrow unworked field of crushed anthracitic coal of Gond- minerals wana (upper palaeozoic) age in Darjeeling District near the Nepal frontier, the coal seams lie mainly in the valleys of two rivers, the Barakar and the Damodar. The principal fields at present worked are at GirTdIh, or Karharbari, in the valley of the Barakar, and at Jherria and Raniganj in the valley of the Damodar. These fields are estimated to be capable of yielding 14,000,000,000 tons of coal, excluding 67,000,000 tons already extracted. They all lie within 200 miles of Calcutta and have been made accessible by rail. The Raj- niahal fields give a small output, and Daltonganj, which has recently been connected by rail with Barun, is being developed. Of the un- worked fields, Karanpura with nearly 9,000,000,000 tons of coal is perhaps the most important. The Auranga, Bokaro, Hutar, and Ram- garh fields are also of value, but they have not yet been opened out by the construction of railways. These fields contain fair steam coals ; some are very good, but they all contain a rather high percentage of ash. Many of them yield a good firm coke suitable for furnaces.

The maximum thickness of the seams is 95 feet, and the portions worked vary in thickness from 2 1/2 to 45 feet. As a rule, a quarry is commenced at the outcrop ; and as it pays to remove a large over- burden from thick seams, a number of huge open excavations are formed. When the cover overlying a seam is too thick to be econo- mically removed, or when the seam is thin, galleries from 8 to 12 feet wide are driven, both on the dip and along the strike of the seam, leaving pillars of coal the size of which varies according to the method of working and the thickness of the seams cover. A system which provides for 12 feet galleries and 12 feet pillars yields at once three- quarters of the coal ; but the remaining quarter, which is left in pillars, can seldom be won. A system allowing 12 feet galleries and 60 feet pillars yields 30 per cent, of coal in the first working, and 70 per cent, is left in pillars ; but unless the seam be more than 20 feet thick, a large proportion of the latter can be obtained in the second, or pillar, work- ing. Pillar working is mainly confined to European-managed mines, as there is always danger of a fire breaking out in large areas of pillars. In driving galleries it is usual to start from the top of the seam with

' The corresponding figures for ilengal as now constituted are: receipts, 8-6 lakhs; expenditure, 5-45 lakhs; and net surplus, 3-15 lakhs. a heiglit of 6 feet, and, after this drive has advanced some distance, to deepen it to the full height of the seam by cutting out the remainder of the coal in successive steps. In a few mines the galleries are commenced in the lower portion of the seam, and are heightened by dropping the coal left above. In the East Indian Railway collieries in the Girldih coal-field the coal is extracted by a combination of the pillar and long wall methods. The lower portion of the seam is cut up into pillars 6 feet in height, and the latter are thinned down till they are only just able to carry the weight of the overlying coal. These thinned pillars are then blown down by dynamite, and the top coal (17 feet thick), which comes away readily from a strong sandstone roof, falls on the floor. When a large area of coal has been extracted, a rib of coal is left against the worked-out portion, or goaf, and a new set of workings is started.

The methods of raising the coal to the surface vary from the primi- tive means of baskets carried on the heads of cooly women to hauling sets of 5 or 10 tubs on inclines provided with rails, or hoisting in well-fitted shafts up to 640 feet in depth by direct-acting engines. All three methods are in vogue in the chief coal-fields. The coal is cut with picks of English pattern and make by natives of many castes, including the aboriginal Santals, Mundas, and Oraons, and the semi-Hinduized Musahars, Bauris, Bagdis, Ghatwals, Mahlis, Turis, Chamars, Telis, and Pasls. The majority are recruited from the villages surrounding the coal-fields, and from the adjoining parts of Bankura, Manbhum, Blrbhilm, and the Santal Parganas.

The underground work is performed at a fixed price per tub of coal by families, or gangs of men, women, and children, who choose their own hours of labour. The men cut the coal, and the women and children carry it to the tubs. As a rule, they also push the tubs to the shaft or incline, but at one colliery no horses and ponies are employed to ' lead ' the coal underground. A man can cut about 2\ tubs (i-^ tons) of coal per day of eight hours; but he seldom works more than five days in the week, and strictly observes all high-days and holidays. The number of working days per year varies from 200 to 300. The total value of coal at the pit's mouth in 1901 was 1-54 lakhs; and as there were 79,652 persons employed, the value of each person's out-turn for the year was Rs. 191. Of this sum, the colliery owner's profit, the landowner's rent or royalty, the cost of stores, tools and equipment, and the superior establishment take about Rs. 98, leaving about Rs. 93 a year as the earnings of each person, or about Rs. 15-8 a month per family.

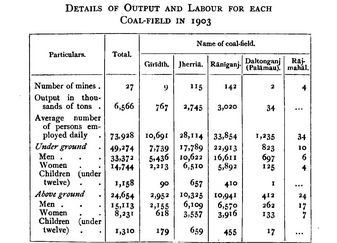

In 1774 Mr. S. G. Heatly (the reputed discoverer of Bengal coal) and Mr. J. Summer applied to Government for the right of working coal at RanTganj. In 1777 six mines were worked and 90 tons of coal were jl)tainecl. Nothing further was done till about 181 5, when a Mr. Jones mined coal from pits and was the first to sell it in the general market. The industry progressed slowly till 1840, when the imports to Calcutta from RanTganj reached 36,200 tons. From 1840 to 1845 there was a constant increase in output, which in 1845 amounted to 62,400 tons. The East Indian Railway tapped the fields in 1854, and in 1858 the out-turn had increased to 220,000 tons. In 1903 the out-turn exceeded 3,000,000 tons, obtained from 142 mines employing 34,000 persons daily. The RanTganj field contains two valuable coal series, which are separated by ironstone shales 1,000 feet thick. The Giridih field was worked from 1857 to 1861, when it was closed for a time; it was reopened and worked systematically in 187 1, and in 1903 its yield was 767,000 tons, from nine mines employing 10,700 persons. It possesses two valuable seams in the lower coal series, and one of the shafts has a depth of 640 feet. Jherria was opened in 1894, but its output in 1903 had already risen to 2,746,000 tons, from 115 mines employing 28,000 persons. As at RanTganj, two coal series exist, the lower one containing eighteen, and the upper one two, valuable seams.

Of these seams, twelve are being worked. The East Indian Railway Company at GTrTdTh, and the Bengal Coal Company in the Daltonganj, GTrTdTh, and RanTganj coal-fields, each raise more than 600,000 tons yearly ; and the output of the Equitable, New Birbhum, and the Barakar Coal Companies exceeds 300,000 tons each. The European- owned collieries raise between them more than 4,000,000 tons, and those owned by natives have an output exceeding i\ million tons. The capital invested in joint-stock companies is about 115 lakhs, and there is also a large but unknown investment by private owners. The total output of the Province in 1881 was 930,000 tons. In 1891 it had risen to 1,747,000, in 1901 to 5,704,000, and in 1903 to 6,566,000 tons.

The railways consume one-third of the total output. The imports of foreign coal into Calcutta, the only important distributing port, which were 70,000 tons in 1880, had dwindled to 2,000 tons in 1901. The exports to foreign ports amounted to 8 tons in 1880, 26,000 tons in 1890, a quarter of a million tons in 1897, and more than half a million in 1 90 1. In Bombay English coal still competes with Indian, for although the latter can be bought in Calcutta for Rs. 7 per ton, the steamer freight and other charges raise its price to Rs. 15 at Bombay, which is only Rs. 2 less than the cost of English coal of better quality. Indian coal reaches Suez on the west and Singapore on the east ; at the latter port it competes with the supply from the Japanese mines.

About 1,700 persons are employed in iron-mining, and practically all the mineral won is dispatched to the works at Barakar, near Asansol, where pig-iron, pipes, and various kinds of castings are turned out. The ore is found in thin alluvial deposits at a number of places, as masses of hematite and magnetite in metamorphic rocks at Kalimati and in the ironstone shales of the RanTganj coal-field. The alluvial deposits were at one time worked by natives. The Kalimati quarries are shallow, and were opened in 1901, when they produced 7,800 tons of ore, rising in the following year to 10,382 tons. The Ranlganj ore is in the form of carbonate below ground, but it readily weathers, and at the surface consists of hematite and limonite. The beds vary from 2 to 8 inches in thickness and form one-seventeenth of the whole series, which is 1,000 feet thick. About 50,000 tons of ore were won in 1901 from shallow trenches and pits. The output of the Province rose from 20,000 tons in 1891 to 58,000 tons in 1901 and to 72,000 tons in 1902. The success of the industry depends in a great measure on the coking qualities of the Bengal coal. Attempts at steel-making have proved unremunerative.

Details of Output and Labour for each Coal-field in 1903

Mica is found over a large area in Gaya, Hazaribagh, and Monghyr Districts. It occurs in dikes and masses of pegmatite, as more or less defined shoots and patches which, in many cases, are found at the surface during the rains and are worked in the cold and hot seasons. In 1903 there were 251 mines and quarries, employing about 6,500 labourers daily. With the exception of Bendi, all the quarries and mines are worked by primitive native methods. Haulage and pumping are done by women, who are seated on ladders and pass up, from hand to hand to the surface, earthen pots filled with water or baskets with mica. The output in 1901 was 914 tons, valued at \\ lakhs, or seven times the quantity obtained ten years previously. Of this amount, 628 tons were obtained by a European firm, which owns a large area of land outside the Kodarma Government forests, where most of the other mines are situated. In 1903 the output had fallen to 692 tons.

Recent gold-bearing sands are widely distributed, and yield poor wages to a few Jhoras working with wooden dishes. Numerous veins of vitreous white quartz and grey quartzites occur in Singhbhum District, and in 1895 several small shafts were sunk. Assays give results varying from I to 7 dwts. per ton. A small amount of prospecting work was done in 1901. Copper pyrites are found at Baraganda, in a band of mica and talcose schists varying from 12 to 40 feet in thickness. The only mine hitherto worked was closed in 1891. The rock contains 3 per cent, of copper, which was increased by concentration to 12 per cent, and the concentrates were carted to Girldih and smelted. In all, 1,100 tons of copper were obtained. At Rajdoha also copper has been worked in small quantities. Alluvial tin is reported from Hazaribagh, but it has not yet been found in paying quantities.

The saltpetre of Indian commerce is obtained mainly from the Patna Division and Monghyr. It occurs as a natural efflorescence on the surface of the ground, and its manufacture affords employment to a large number of people belonging to the caste (Nunia) named after it. The quantity produced in 1900 is estimated at 160,000 cwt., valued at 12 lakhs, or rather less than the out-turn in 189 1. In 1903 the out-turn was 382,000 cwt., of a total value of 22-33 l!il<hs.

Slate has been quarried in Monghyr for many years, and is now mined. The industry gives employment to nearly 400 persons, and 1,600 tons were produced in 1903. There are two beds of slate on edge, 13 and 9 feet thick respectively. Owing to ' creep ' in the hill-side, quarrying has been given up and underground chambers are now cut, from 15 to 25 feet in height, leaving a minimum cover of 30 feet. The slates are thicker than Welsh slates, but are strong and suitable for the flat roofs of Indian bungalows. The castes employed are chiefly Koras, Musahars, Beldars, Gonrs, Nunias, Chamars, and Goalas.

Limestone is widely distributed in the nodular form known as kankar, except in the deltaic tract east of the Bhaglrathi. In 1900 the out-turn was 100,000 tons, valued at three-quarters of a lakh. Sandstone, suit- able for building and road-making, is found in the coal-fields. An output of 40,000 tons, valued at a quarter of a lakh, was reported in 1900. Laterite is found in Bihar and Orissa ; 100,000 tons, valued at half a lakh, were raised in 1900. Granite and other igneous rocks are used in Gaya and Hazaribagh for road-metal. Soapstone occurs in Manbhum, and is made into cups and images, but the industry is small.