Bengal: Arts and manufactures, 1908

This article has been extracted from THE IMPERIAL GAZETTEER OF INDIA , 1908. OXFORD, AT THE CLARENDON PRESS. |

Arts and manufactures

Throughout the Province various handicrafts are carried on, but, as a rule, the articles manufactured sufifice only to meet the local demand. Dacca* and Santipur were formerly manufactures for their fine mushns ; and early in the nine- teenth century the quantity exported to Europe, and especially to France, was very great. From Dacca* alone the exports in 1817 were valued at 152 lakhs. Ordinary cotton goods were also in great demand for the European market, and as early as 1706 efforts were made to induce weavers to settle in the neighbourhood of Calcutta. The introduction of machinery in Europe has not only killed the export trade, but has flooded the country with cheap piece- goods and seriously crippled the local weaving industry. Country-made goods, however, are more durable, and, in the more remote parts, country weavers have maintained their business. The weavers of Serampore, who use an improved loom, still hold their own, and so do those of Dacca*, where a carefully bleached white cloth with a border of gold thread is made ; while in Patna District the trade in cotton goods and cheap muslins made at Dinapore is still fairly brisk. Cotton- spinning, except as a domestic industry, no longer exists, and the weavers generally work with imported yarn or cotton twist.

Jute is worked up into cloth for gunny-bags, sails, and quilts, mainly in Hooghly and Dacca*, but smaller quantities are manufactured in most parts of Bengal proper. This work is the speciality of the Kapali caste. The yarn is prepared by the men, and the women weave the cloth. Jute is also twisted into twine from which ropes are afterwards made.

The silkworm is reared in West Bengal and in the tract where the Presidency and RSjshahi* Divisions meet. The industry was threatened with extinction, owing to diseases among the worms ; but the subject has been investigated by Government agency, and remedies have been applied with a fair measure of success. Silk-reeling is carried on in both European and native filatures, and raw silk is largely exported, the value of the exports amounting in 1903-4 to 47 lakhs. Silk thread is twisted from the reeled silk by women, and is knotted and uneven. The cloth woven is thus of a rough quality, but in spite of this silk- weaving was once a flourishing industry. Of late years it has suffered greatly from the competition of silks made in Japan, China, and Italy, and the value of manufactured silk exported in 1903-4 was estimated at only 6 lakhs compared with 18 lakhs in 1881. The weaving of mulberry silk, which is made chiefly for export, is carried on in Murshidabad and several Districts of West Bengal. That of tasar silk, which is in demand among natives, who wear it when performing religious ceremonies, has its head-quarters in West Bengal, Manbhum, and Gaya ; the business is still fairly prosperous, but, as the worm is not cultivated and the cocoons are collected in the jun^^le, the supply is very fluctuating. In East Bengal muga silk from Assam is woven, and in North Bengal a rough cloth is made by the Mech women from the silk of the eri worm. A mixed cloth, the warp of which is tasar silk and the woof cotton, is woven at Dacca*, Bhagalpur, and Bankura.

I-ocally made cloths and English cloths of similar texture are embroidered in coloured silks and cottons at Santipur by the women of the weaving class, but the arrangement of colours is not very pleasing. Embroidered caps are made at the town of Bihar. Skilled embroiderers in gold and silver are found at Patna and Murshidabad, but their work is chiefly confined to caps and to the trappings of horses and elephants. In Calcutta and the neighbourhood, the fancy work known as chikan is a thriving industry, and there is a considerable demand for it in EuroDe.

Cotton carpets are made at Nisbetganj in Rangpur* and at a few places in Bihar. The weaving of woollen goods is carried on only in Bihar and in part of Murshidabad District ; but the industry is almost entirely confined to the manufacture of blankets, which are made for the most part by the shepherds themselves. The cloth is woven in narrow strips which are afterwards stitched together. Woollen carpets of good texture are made at Obra in Gaya District.

The filigree gold- and silver-work of Cuttack and Dacca* is well- known. The silver-work of Kharakpur in Monghyr is famous, and there are also skilled workers in Calcutta. Blacksmiths and workers in iron are found everywhere, but most of them are employed in the manufacture and repair of agricultural implements and other articles of general use. In Patna, Calcutta, and Kishanganj (Purnea), iron cages, platters, spoons, chains, bolts, «Scc., are made. A few cutlers work in the suburbs of Calcutta, at Kanchannagar near Burdwan, and at one or two other places. Padlocks and keys are manufactured on a small scale at Natagarh and elsewhere. Monghyr was famous for its iron- workers before the days of foreign competition, and it still holds a relatively high position. Its speciality is the making of shot-guns ; but during the last few years the business has declined, and in 1901 only 463 guns were manufactured, or less than one-sixth of the out-turn four years previously. The number of fire-arms exported in 1903-4 was 899. This is attributed by the dealers in arms partly to the effect of foreign competition, and partly to the reduced number of gun licences issued in recent years. The manufacture of brass and copper utensils is the one indigenous industry which has not suffered from foreign competition. Figures, supports for /lukkas, hinges, and the like are sometimes moulded ; but the chief articles manufactured are do- mestic utensils, vessels of brass being used by Hindus and of copper by Muhaniniadans. They are made either by casting and moulding, or by joining together pieces of beaten-out metal, which at the present day is usually imported in sheets from Europe. The methods employed are of the simplest, and practically no machinery is used.

The manufacture of earthen vessels is carried on everywhere in Bengal, but the best ware is made in Burdwan District, on the banks of the Bhaglrathi, where the clay is especially suitable for the manufacture of durable pottery. Black earthen jars are exported in large quantities from the Satkhira subdivision of Khulna, and are used for storing oil and grain. In Monghyr porous water vessels are made, and decorated pottery of graceful form is produced at Sasaram. Ornamental pottery is also made at Siwan in Saran, which is remarkable both for its shape and decoration. The vessels are baked in earthen jars to prevent con- tact with the flames ; they thus become black when baked, and are then glazed with a mixture of clay and fuller's earth. Owing partly to the absence of suitable clay, and partly to the fact that Hindus think it necessary to change their earthen vessels constantly, nothing has yet been done in Bengal towards the production of porcelain or white earthenware. Glazes also are rarely resorted to. Occasionally vessels are smeared, before burning, with a mixture of fine clay, but the art of fusing glazes is not understood. Clay figures of some merit are moulded at Krishnagar, and idols with no pretensions to artistic skill are made everywhere.

Stone-carving, as an art, is practised only in Gaya, where small statues of gods and figures of animals are made of granite ; the carving of stone for the decoration of temples and buildings has almost entirely died out in Bengal. Glass-ware is made, chiefly in Patna, from Son river sand mixed with carbonate of soda. The glass is green and clouded, but at Patna a fair amount of white glass is now made. Bottles for holding perfumery, lamps for illuminations, and glass bangles are the chief articles produced. Bracelets of coarse glass are also made at Bhagalpur.

The ordinary carpenter of Bengal is a very rough workman, and is capable of little beyond the making of ploughs and other simple articles in common use among the people. In North and East Bengal, Orissa, and Chota Nagpur, the number even of such carpenters is deficient. Carving in wood was formerly practised as an adjunct to architecture, and there are traces of the skill of former workmen in the carved bal- conies of Patna, Gaya, and Muzaffarpur. This sort of work has almost entirely died out ; and the only indigenous wood-carving deserving of mention at the present time is that of the ebony workers of Monghyr, who make pieces of furniture, boxes and other small articles, which are inlaid with patterns in horn and ivory. In some parts, especially in the Patna Division, carpenters have been taught by Europeans to make articles of furniture from European models, and they often acquire great accuracy and finish. In Calcutta there are now numerous cabinet- makers who learnt their art in the English shops. In Muzaffarpur hukka stems are turned, and over 200,000 are exported yearly ; pdlkis and cart-wheels are also manufactured on a large scale.

Conch-shell bracelets are made chiefly in Dacca*. They are sawn out by a large metal disk, and are then polished and coloured. Bengal has always been famous for its ivory-carving, the peculiar feature of which is the minuteness of the work, which requires about eighty different tools. The number of persons now employed is, however, very small, and consists only of a few families in Murshidabad, Rang- pur*, and Cuttack. Metal inlaying is practised in a few places, the best known being the so-called hidri work of Purnea and Murshidabad, which was introduced from the Deccan, and consists of inlaying with silver a sort of pewter, which is made black with sulphate of copper.

Mat-making is largely carried on in South Midnapore, whence comes the cyperus matting sold in Calcutta, and mats of fine reeds are woven in various parts of East Bengal. Bamboo mats and baskets are made everywhere, and fancy baskets of coloured grasses in Bihar. The in- digenous Chamar, or leather-dresser and cobbler, is found all over the Province ; but his work is very rough and is confined to meeting the simple requirements of ordinary village life — the supply of leather straps for plough yokes, rough shoes, and the like. In Calcutta a number of shoemakers working in the European style are found, com- prising both Chinamen and natives of the country. Leathern harness is made on a small scale in Calcutta and Patna.

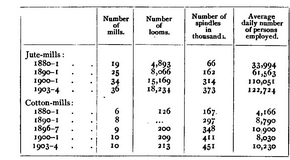

The extended use of jute, as a fibre, dates from 1832, when experi- ments made in Dundee showed that it could be used as a substitute for hemp ; and a further impetus was given to the demand when the diffi- culties which once existed in bleaching and dyeing it were overcome. It is used not only for the making of gunny-bags and coarse cloth, but also in the manufacture of carpets, curtains, and shirtings, and is largely mixed with silk or used for imitating silk fabrics. The rapid spread of jute cultivation during recent years has already been described. The whole of the raw material, except such as was required for the hand- looms of the villages, was formerly exported to Europe, mainly to Dundee ; but of late a flourishing local industry has been established, and the banks of the Hooghly are now lined with jute-mills, which are rapidly growing in number and importance. In 1903-4 there were 36 mills with 18,000 looms, employing 122,724 hands, compared with 25 mills with 9,000 looms and 66,000 hands in 1892-3. Nearly half the raw jute produced in Bengal is now consumed in the.se mills ; the value of gunny-bags, rope, and other goods exported in 190 1-2 was 859 lakhs, against only 100 lakhs twenty years previously ; and the export had further increased by 1903-4 to 936 lakhs. Jute presses are also increasing rapidly in number; in 1903 there were 155, compared with 37 in 1892 and only 4 in 1882.

The great centre of the Indian cotton-manufacturing industry is in Bombay, but it is steadily growing in importance in Bengal, and there are now ten mills employing about 11,000 hands, compared with an average of six mills employing 6,000 hands in the decade 1881-90. In 1903-4 the out-turn of yarn exceeded 46,000,000 lb. and that of cloth w-as nearly 700,000 lb. The capital invested has risen from 83 to 177 lakhs.

The principal statistics in connexion with the jute and cotton indus- tries are shown in the following table : —

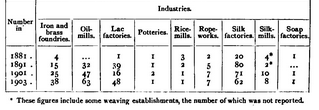

There were in 1903 four paper-mills with a capital of 50 lakhs, em- ploying on the average nearly 900 hands each, and producing nearly 36,000,000 lb. of paper. The capital invested and the production have quadrupled since 1881-90. Other large industries are also growing apace, such as iron and brass foundries, oil-mills, silk, soap, and lac factories, potteries, rope works, &c. ; and for miles above Calcutta the banks of the Hooghly present a scene of industrial activity which bids fair in time to rival that of the largest towns in Europe. The principal statistics of these undertakings are shown in the following table : — •

These industries are at present worked chiefly under European sui)er- vision and supported by European capital. It may be hoped that in time the natives of the country will follow the lead thus given them.

It is said that the supply of labour for these large industries has not kept pace with the rapidly growing demand, but in spite of this the number returned as employed in 1902 aggregated 253,000, compared with 247,000 ten years earlier. The real increase is much greater, as many industries employing less than twenty-five persons have been left out of account in recent years ; and if allowance be made for these, the total number of labourers employed in 1902 may be estimated at 275,000.

The returns for 1903 show altogether 261,656 persons employed. These labourers come chiefly from Bihar and the United Provinces and, to a less extent, from Chota Nagpur. The wages ofl"ered by the mills are nearly double those obtained by unskilled labourers in the tracts whence they chiefly come ; and, although the cost of living is also higher, there is no doubt that the rapid expansion of this field of employment is a great boon to the poorer classes. Their main object is to save as much money as they can for the support of their families at home or as a provision for their old age. In the meantime, they live huddled to- gether in crowded lodging-houses as close as possible to the mills and factories where they work ; but in other respects they fare far better than they would do in their own country, and their dietary is much more liberal and of a far better quality than that to which they are accustomed at home.

See also

For a large number of articles about Bengal, extracted from the Gazetteer of 1908 (as well as other articles on Bengal) please either click the 'India' link (below, left) and go to Bengal (under B) or enter 'Bengal' in the 'Search' box (top, right).

Bengal: A history, by British Raj writers

Bengal: Agriculture in A.D. 1900

Bengal: Arts and manufactures, 1908

Bengal: Commerce and trade, c. A.D. 1900

Bengal: Mines and minerals, c. A.D. 1900