Semiconductors: India

This is a collection of articles archived for the excellence of their content. |

Dictionary.cambridge.org spells semiconductors as one word, without a hyphen.

Contents[hide] |

History

Early efforts at semi-conductor manufacturing

N Dayasindhu, April 12, 2024: The Times of India

India aspires to enter the global top five in semiconductor manufacturing by 2030. The country’s first modern commercial fab is expected to manufacture 110nm to 28nm ICs (integrated circuits). Three outsourced semiconductor and assembly testing facilities will become operational soon. The govt is supporting these projects with a sizable investment.

The beginning | The focus on semiconductor manufacturing is making up for the lost time. While it is true that India did not have large-scale fabs and assembly and testing facilities, we do have a niche semiconductor manufacturing capability housed in two public sector organisations – Bharat Electronics Ltd (BEL) and the erstwhile Semiconductors Complex Ltd (SCL), which is now Semiconductor Laboratory.

ICs for clocks, radios | BEL was established by the govt in the 1950s in the pre-IC era to manufacture communication equipment, valves, and germanium semiconductors. By the late 1970s and early 1980s, BEL was manufacturing digital bipolar and digital C-MOS type small and medium scale ICs for use in clocks, single chip radios, audio amplifiers, tape recorders and TVs. In the mid1980s, BEL had a 75% market share for ICs used in black and white TVs. BEL also had ICs for colour TVs, but these were not as successful since colour TV manufacturers imported these ICs as part of knocked-down kits. BEL’s ICs were not exact re- placements of ICs recommended by the OEM who made the kits, and required a design effort from the Indian TV manufacturer. US collaboration | BEL had a technology collaboration with American electronics company RCA from the 1970s which allowed it to produce many of RCA’s ICs. RCA also helped BEL to train its engineers in semiconductor manufacturing. BEL’s manufacturing set-up was for 5-micron (5000nm) ICs. BEL did not have a high utilisation due to limited domestic demand. The cost to import the latest equipment was very high given the context in the 1980s. BEL tried but had limited success in exporting ICs.

Import substitution in telecom | BEL had an IC design team. Even with a limited CAD infrastructure, the BEL design team was successful in designing a few ICs for telecommunications. One of these designs replaced an IC imported by the Indian Telephone Industries (ITI) and was more than 50% cheaper for the same functionality. Incidentally, ITI had its prototype production line for the fabrication of 5-micron and 3-micron LSI/VLSI chips.

Talent attracts MNCs | BEL was a sought-after employer for freshly minted engineers in that era since it offered an excellent in-house training programme. The presence of high-quality talent in BEL and ITI was one of the reasons why Texas Instruments located its R&D GCC in Bengaluru in the mid-1980s. BEL’s and ITI’s design talent was the bedrock of the R&D services industry focusing on semiconductors. Today BEL is recognised for its prowess in manufacturing defence electronics systems. BEL also manufactures the electronic voting machines used in the Indian elections.

LSI, VLSI IC mfg | The Semiconductors Complex (SCL) started manufacturing LSI and VLSI ICs in the early 1980s. SCL’s products included clock-watch chips, codecs, 8-bit microprocessors, etc. SCL produced memory chips of 16K RAM using imported ready wafers. This was a late entry, given that 16K RAM was nearing obsolescence in the global market. Global collaborations help | SCL started with a 5-micron production technology. It used its capabilities to enhance this to 2-micron technology. SCL collaborated with American Microsystems to establish a value chain for LSI design, mask fabrication, wafer fabrication, and assembly at 5-micron. SCL also had an agreement with Hitachi to manufacture watch modules. Another agreement was with Rockwell to manufacture the 8-bit 6502 microprocessor. This microprocessor was used in computers like the Apple II, Commodore 64, and BBC Micro.

Fire damage | In its heydays, SCL had a 60-engineer design team. SCL also had a dedicated group developing indigenous CAD software. A major fire in 1989 caused serious damage to SCL’s production facilities. It took almost a decade for SCL to recover from this fire and has now transformed into the Semiconductor Laboratory under the department of space.

N Dayasindhu is a co-founder of itihaasa Research and Digital Indian semiconductor manufacturing in the 1980s was a technology demonstrator. The Indian macroeconomic context in that era was not conducive to taking big financial bets on emerging technologies when forex was scarce. In that era, the Indian domestic demand was not enough to sustain a world-class and world-scale semiconductor manufacturing industry. Today, we already have one of the world’s best semiconductor design talent pools. We need to extend our expertise to the manufacturing part of the value chain.

Chip manufacturing

2020, 2021

From: June 22, 2022: The Times of India

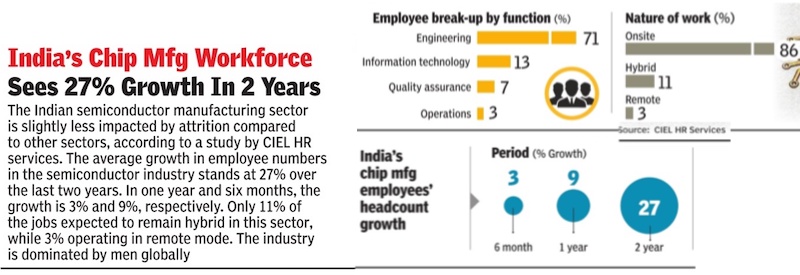

See graphic:

Chip manufacturing: employee headcount in India, presumably as in 2020, 2021

Research

India vis-à-vis the world, 2018-23

From: March 12, 2025: The Times of India

See graphic:

Research on semiconductors in China, the USA, India, Japan and South Korea, 2018-23