Textiles sector: India

This article has been sourced from an authoritative, official readers who wish to update or add further details can do so on a ‘Part II’ of this article. |

The source of this article

INDIA 2012

A REFERENCE ANNUAL

Compiled by

RESEARCH, REFERENCE AND TRAINING DIVISION

PUBLICATIONS DIVISION

MINISTRY OF INFORMATION AND BROADCASTING

GOVERNMENT OF INDIA

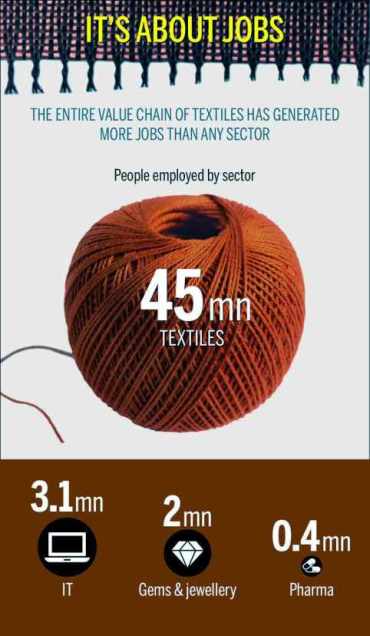

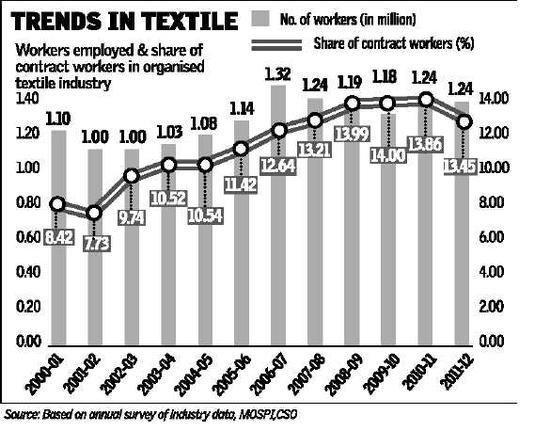

TEXTILES

The Indian Textiles Industry has an overwhelming presence in the economic life of the country. Apart from providing one of the basic necessities of life, the textiles industry also plays a pivotal role through its contribution to industrial output, employment generation, and the export earnings of the country. Currently, it contributes about 12 per cent to industrial production, 4.0 per cent to the GDP, and 12 per cent to the country’s export earnings. It provides direct employment to over 35 million people, which includes a substantial number of SC/ST, and women. The Textiles sector is the second largest provider of employment after agriculture. Thus, the growth and all round development of this industry has a direct bearing on the improvement of the economy of the nation.

Due to policy measures initiated by the Government in the recent past, the Indian Textiles Industry is in a stronger position than it was in the last six decades. The industry which was growing at 3-4 per cent during the last six decades has now accelerated to an annual growth rate of 8-9 per cent in value terms. The catalyst for this exponential growth is a buoyant domestic economy, substantial increase in cotton production, a conducive policy environment provided by the Government and the end of the Multi Fibre Arrangement (MFA) on December 31, 2004. The rationalization of fiscal duties undertaken during the last few years has also provided a level playing field in all segments of the industry resulting in the holistic growth of the industry. A strong foundation for industry has been laid on which world class manufacturing units can realize their full potential and make a mark in the international economy.

The growth manifests through a consistent increase in production of fabric and investments. During 2010-11, the production of fabric was 61.81 billion sq. mtrs (Prov.), as compared to 49.58 billion sq. mtrs in 2005-06. The textiles sector has witnessed a spurt in investment. The Technology Upgradation Fund Scheme (TUFS), encouraged investment of more than Rs.2,11,000 crores as on 30.06.2011. The restructured TUFS was implemented w.e.f. 28.04.2011 and is expected to trigger additional investments of over Rs.46,900 crores during the balance period of the 11th Five Year Plan. This investment is also expected to generate more employment.

Capital

India Today , Capital “India Today” 1/8/2016

See graphic

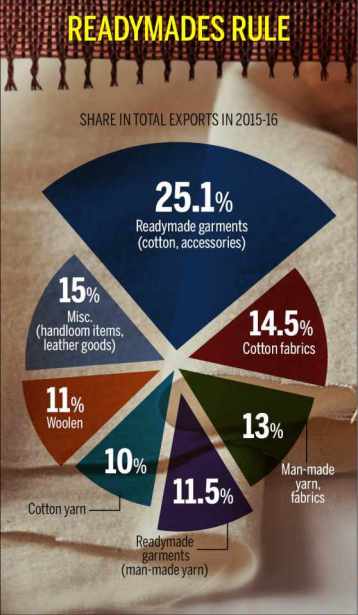

EXPORTS

See graphic

India's textiles and clothing industry is one of the mainstays of the national economy. It is also one of the largest contributing sectors of India's exports worldwide. The Vision Statement for the textiles industry for the 11th Five Year Plan (2007-12), interalia, envisages India securing a 7% share in the global textiles trade by 2012. At current prices the Indian textiles industry is pegged at US$ 55 billion, 64% of industrial production, which is 4% of GDP, employs 35 million people and accounts for nearly 12% share of the country's total exports basket.

The export of textiles and clothing aggregated to US$ 22.41 billion in 2009-10. As per latest available provisional figures, exports of textiles and clothing aggregated to USD 26.82 billion during 2010-11 (against the target of USD 25.48 billion) registering an increase of 19.6% over exports of 22.41 billion in 2009-10. Readymade garments account for almost 45% of the total textiles exports. Apparel and cotton textiles products together contribute nearly 70% of the total textiles exports. The exports basket consists of a wide range of items comprising readymade garments, cotton textiles, handloom textiles, man-made fibre textiles, wool and woolen goods, silk, jute and handicrafts including carpets. India's textiles products, including handlooms and handicrafts, are exported to more than a hundred countries.

However, the USA and the EU, account for about two-third of India's textiles exports. The other major export destinations are Canada, U.A.E., Japan, Saudi Arabia, Republic of Korea, Bangladesh, Turkey, etc. Keeping this trend in view, a target of USD 32.35 billion has been fixed by the Government for 2011-12.

2015-16

See graphic

Stiff competition

See graphic

Employment

India Today , Textile “India Today” 1/8/2016 See graphic

TECHNOLOGY UPGRADATION

In order to facilitate modernization/technology upgradation of textiles mills, Government had launched Technology Upgradation Fund Scheme (TUFS) for Textile and Jute Industries w.e.f. 1.4.1999 for a period of 5 years which was subsequently extended up to 31.3.2007. The scheme was continued in modified form w.e.f. 01.04.2007 to 28.06.2010. The scheme has again been launched in restructured form for the period 28.04.2011 to 31.03.2012.

It is a credit linked scheme and provides following benefit: Reimbursement of 5% points on the interest charged by the lending agency on project of a technology upgradation in conformity with the schemes, for spinning machinery the scheme will provide 4% for new stand alone/replacement/ modernisation of spinning machinery; and 5% for spinning units with matching capacity in weaving/knitting/processing/garmenting; cover for foreign exchange rate fluctuation/forward cover premium not exceeding 5% for all segments except for new stand alone/replacement/modernisation of spinning machinery, the foreign exchange rate fluctuation/forward cover premium will be 4%; additional option to the powerlooms units and independent perpetratory units to avail of 20% margin money subsidy under Restructured TUFS in lieu of 4% interest reimbursement on investment in TUF compatible specified machinery; subject to a capital ceiling of ` 500 lakhs and ceiling on margin money subsidy Rs.60 lakhs. However, for brand new shottleless looms the ceiling on margin money subsidy will be Rs.1 crore.

Under Restructured TUFS (28.04.2011 to 31.03.2012), this office has provided UID to 87 applications with total project cost of Rs.4054.62 crores and subsidy requirement of Rs.69.99 crores upto 31.03.2012 as on 30.08.2011.

TECHNICAL TEXTILES

Technical textiles are materials and products used for their technical performance and functional properties. These products have a presence in major areas of activity such as, aerospace, shipping, sports, agriculture, defence, medicine/health, manufacturing, etc. Technical textiles are an emerging industry with a huge potential to attract investment. The global market size of technical textiles was US$127 bn for the year 2010 and it is expected to reach to US $ 136 bn by the year 2012-13 at an annual growth rate of 3.5% as per David Rigby Associates Report. The Domestic market size of technical textiles during the year 2001-11 was Rs.57,106 crore and it is expected to increase to Rs.70,151 crore by the year 2012-13 at 11% year on year.

To tap the potential of technical textiles and to unleash the investments in this industry, the Government has launched Scheme for Growth & Development of Technical Textiles (SGDTT) during the year 2007-08. Under SGDTT, four Centres of excellence (COEs) have been set up. The COEs identified are The Mills Research Association (SASMIRA) for Agrotech, Northern India Textile Research Association (NITRA) for Agrotech, Northern India Textile Research Association (NITRA) for Protech and South India Textile Research Association (SITRA) for Meditech. The COEs have almost been established and they have started providing assistance to the industry to facilitate investment in this sector. So far, more than 60 seminars/ workshops/training programmes on technical textiles have been organised across the country to attract investors. Baseline survey on technical textile industry in India was conducted and the report is placed in the website www.technotexgov.in

The Government has also launched the Technology Mission on Technical Textiles (TMTT) during December 2010 with two Mini-Missions for five years (2010- 11 to 2014-15) with a financial outlay of Rs.200 crore.

Under the Mini Mission—1 of TMTT, in addition to existing four COEs, four new Centres of Excellence (COEs) are being created for Sportech, Non-Wovens, Indutech & Composites segments. The COIEs identified are DKTE Society's Textile & Engineering Institute, Ichalkaranji, Maharashtra for Non-Wovens; PSG College of Technology, Coimbatore, Tamil Nadu for Indutech; Ahmedabad Textile Industry's Research Association (ATIRA), Ahmedabad, Gujarat for Composites; and Institute of Chemical Technology, Mumbai for Sportech.

SCHEME FOR INTEGRATED TEXTILES PARKS

Scheme for Integrated Textile Parks was approved in the 10th Five Year Plan to provide the industry with world-class infrastructure facilities for setting up their textile units by merging the erstwhile 'Apparel Parks for Exports Scheme (APES)' and 'Textile Centre Infrastructure Development Scheme (TCIDS).

The Scheme targets industrial clusters/locations with high growth potential, which require strategic interventions by way of providing world-class infrastructure support. The project cost covers the cost of common infrastructure and buildings for production support activities, depending on the needs of the ITP. There will be flexibility in setting up ITPs to suit the local requirements.

This scheme is implemented through Special Purpose Vehicles (SPVs), where, Industry Associations/Group of Entrepreneurs are the main promoters of the Integrated Textile Park (ITP). At each ITP, there would be a separate Special Purpose Vehicle (SPV) formed with the representatives of local industry, Financial Institutions, State Governments and the Central Government. SPV shall invariably be a Corporate Body registered under the Companies Act. Any different structure for the SPV requires the approval of the Project Approval Committee. The SPVs shall have operational autonomy so that they do not become surrogate Public Sector Enterprises or be controlled by Central/State Governments.

The components of an ITP are broadly divided in the following groups :

(a) Group A : Land.

(b) Group B : Common Infrastructure like compound wall, roads, drainage, water supply, electricity supply including captive power plant, effluent treatment, and telecommunication lines etc.

(c) Group C : Buildings for common facilities like testing laboratory, design center, training center, trade center/display center, warehousing facility/raw material depot, creche, canteen, workers hostel, offices of service providers, labour rest and recreation facilities etc.

(d) Group D : Factory buildings for production purposes.

(e) Group E : Plant and machinery.

The total project cost for the purpose of this scheme includes the cost on account of components of ITP, as listed under Groups A, B, C and D above, provided the ownership of the factory buildings vests with the SPV. The SPV will, however, have the option of seeking financial support from Government of India for components under Groups B and C only, if factory buildings are individually owned.

A panel of professional agencies has been appointed as Project Management Consultants (PMCs) for implementing the Scheme.

The PMCs will be responsible for the speedy implementation of the Projects in a transparent and professional manner so as to achieve high degree of quality at a low cost acceptable to the members of the SPV for which fee will be paid to the PMCs by the Ministry of Textiles. The PMCs will report to Ministry of Textiles, which shall directly supervise the implementation of projects under the superintendence and control of Secretary (Textiles).

Funding Pattern

The Government of India's (GOI) support under the Scheme by way of Grant or Equity will be limited to 40% of the project cost subject to a ceiling of Rs.40 crores. GOI support under the Scheme will be generally in the form of grant to the SPV unless specifically decided to be equity. However, the combined equity stake of GOI/State Government/State Industrial Development Corporation, if any should not exceed 49%.

However, GOI support will be provided @ 90% of the project cost subject to a ceiling of Rs.40 crores for first two projects in the States of Arunachal Pradesh. Assam, Manipur, Meghalaya, Mizoram, Nagaland, Tripura, Sikkim and Jammu & Kashmir.

STATUS OF IMPLEMENTATION

Textile Centre Infrastructure Development Scheme (TCIDS) : (202-28th July 2011)

• 18 Projects sanctioned

• GOI Share Rs.268.86 crores.

• Released Rs.210.59 crores.

• Four Projects completed, Kannur-Kerala, Bhiwandi-Maharashtra, and Tirupur- Tamil Nadu, Pandesara-Surat.

• One project nearing completion i.e. SEWA-Gujarat. Apparel Parks for Exports Scheme (APES) : (2002-28th July 2011)

• 12 Projects sanctioned.

• GOI Share Rs.185.22 crores.

• Released Rs.130.85 crores.

• Four Projects completed—Bangaluru-Karnataka, Thiruvananthapuram-Kerala, Tirupur-Tamil Nadu, and Tronica City-Uttar Pradesh.

• One project of Kanpur-Uttar Pradesh nearing completion (Training centre component yet to be completed.)

Scheme for Integrated Textile Park (SITP): (September 05-28th July 2011)

• As per the target, forty (40) Textiles Park projects have been sanctioned.

• Estimated project cost (for common infrastructure and common facilities) of the 40 sanctioned projects is Rs.4133.09 crores of which Government of India assistance under the scheme would be Rs.1419.69 crores. The projects are as under- Andhra Pradesh (5), Gujarat (7), Maharashtra (9), Tamil nadu (8), Rajasthan (5), Karnataka (1), Punjab (3), West Bengal (1), Madhya Pradesh (1).

• An amount of Rs.992.43 crores has been released under SITP.

• 2292 entrepreneurs will put up their units in these parks covering an area of 4307.97 acre. The estimated investment in these parks will be Rs.19456.90 crores and estimated annual production will be Rs.33568.50 crores.

• Seven projects have been completed—Brandix & Pochampally-Andhra Pradesh, Gujarat Eco Textile Park & Mundra-Gujarat. Palladam Hi-Tech Weaving Park, Karur—Tamil Nadu and Islampur Integrated Textile Park, Maharashtra, Production has been started in 24 out of 40 projects.

MEGA CLUSTER

The schemes for mega cluster support weavers/artisans, both in and outside the cooperative fold, including those in Self Help Groups (SHGs), Non Governmental Organisations (NGOs) etc. The schemes provide for development of all the facets of selected clusters like raw material support, design inputs, up-gradation of technology, infrastructure development, marketing support, welfare of weaves etc.

A convergence of the existing development interventions of the Ministry of Textiles & other Ministries/Departments will be affected in these cluster. The schemes also raise living standards of the weavers/artisans by improving the infrastructure facilities, with better storage facilities, technology up-gradation in pre-loom/onloom/ post-loom operations, weaving shed, skill up-gradation, design inputs, health facilities etc.

The development of 6 Mega Clusters in Handloom, Handicrafts and

Powerlooms were first announced by the Finance Minister in his Budget Speech

2008-09. Consequently, following three Central Sector Plan Schemes were approved

by the Cabinet Committee on Economic Affairs (CCEA) in the meeting held on

20.11.2008:

i) Comprehensive Powerloom Cluster Development Scheme

ii) Comprehensive Handloom Cluster Development Scheme

iii) Comprehensive Handicrafts Cluster Development Scheme.

Based on Budget Announcement made in 2008-09, 2009-10 and 2010-11, 12 centres are being developed as mega cluster on a Public Private Partnership (PPP) model to scale up infrastructure and production in Handloom, Handicrafts and Powerloom sectors, wherein Government contribution has been earmarked at maximum of Rs.70 crore for each mega cluster. At present, following 12 centres are being developed as Mega Cluster :

Table

Handlooms Handicrafts Powerloom

4 Mega Cluster 5 Mega Clusters 3 Mega Clusters

1. Varanasi (U.P.) 5. Moradabad (U.P.) 10. Bhiwandi (Maharasthra) 2. Sivsagar (Assam) 6. Narasapur (A.P.) 11. Erode (Tamil Nadu) 3. Murshidabad (W.B.) 7. Bhdohi-Mirzapur (U.P.) 12. Bhilwara (Rajasthan) 4. Virudhunagar (T.N.) 8. Srinagar (J&K) 9. Jodhpur (Rajasthan)

Table ends

NATIONAL TEXTILE CORPORATION (NTC)

NTC has modernized 18 mills, which are now generating cash profits.

E-auction for Sale of Land

For the first time in the history of NTC, online e-auction of sale of surplus land has been introduced with the approval of Assets Sale Committee (ASC) :

• 2.39 acres land of Podar Mill (Process house), Mumbai was put on e-auction from 29th to 31st July, 2010. A total of 8 parties who had deposited the EMD participated in the online e-auction. As against the reserve price of Rs.250 crores, the highest bid was of Rs.474 crores by M/s Indiabulls Real Estate. The offer of M/s indiabulls worked out to Rs.198 crores per acre or Rs.45,000 per sq. ft.

• The second online e-auction of Bharat Textile Mills, Mumbai, admeasuring 8.37 acres took place from 4th to 6th August, 2010. A total of 7 parties who had deposited the requisite EMD participated in the online e-auction. As against the reserve price of Rs.750 crores, the highest bid offered was Rs.1505 crores by M/s Indiabulls Real Estate.

• As its third success towards online e-auction conducted from 29th to 31st December, 2010, the company has bagged Rs.118.40 crores, against the reserve price of Rs.41.27 crores, by sale of 8.21 acres of plot of New Manekchowk Textile Mills, Ahmedabad.

NTC was given the privilege of being the official licensee against the home ware category of Commonwealth merchandise for supply of bed sheets, duvets, towels etc. to Commonwealth Games Village.

RAW MATERIAL

COTTON

Cotton is one the principal crops of the country and is the major raw material for the domestic textiles industry. It provides sustenance to million of farmers as also the workers involved in cotton industry, right from processing to trading of cotton. The Indian textile industry consumes a diverse range of fibres and yarn, but is predominantly cotton based. The ratio of the use of cotton to man-made fibres and filament yarns by the domestic industry is about 56.94. Indian Textile Industry has an overwhelming presence in the economic life of the country.

Apart from providing one of the basic necessities of life, the textile industry also plays a pivotal role through its contribution to industrial output, employment generation and the export earnings of the country. It contributes about 14% to the industrial production, 4% to the GDP and 14.42% to the country's export earnings. The textile sector is the second largest provider of employment after agriculture. Hence, growth and all around development of cotton and cotton industry has a vital bearing on the overall development of the Indian economy.

Cotton is produced in India in three zones viz., Northern Zone comprising the State os Punjab, Haryana and Rajasthan, Central Zone comprising the States of Maharashtra. Madhya Pradesh and Gujarat and Southern Zone comprising the States of Andhra Pradesh, Karnataka and Tamil Nadu. Besides these nine States, cotton cultivation has gained momentum in the eastern State of Odisha.

In India nearly 35% area under cotton cultivation is irrigated and rest 65% is under rainfed especially a central and southern zones of the country.

Indian Cotton Varieties

India is the only country to grow all four species of cultivated cotton Gossypium arboreum and herbaceum (Asian cotton), G. barbadense (Egyptian cotton) and G. hirsutuim. India produces large number of cotton varieties and hybrids. Though the number of varieties in cultivation exceeds seventy-five, 98% of the production is contributed by about 25 varieties only.

Cotton Acreage

With the turn-around achieved in cotton production beginning cotton season 2004- 05, cotton farmers in the country encouraged by higher yields per hectare and resultant increase in their net income from cotton production, have exhibited a clear inclination for cotton cultivation in preference to other competing cash crops. With receipt of good prices for their produce in cotton season 2009-10 as compared to other competing crops, the cotton farmers made up for the increased acreage under cotton by switching over from other crops. As a result, the overall acreage under cotton in cotton season 2010-11 has reached at 111.42 lakh hectares as against the acreage of 103.10 lakh hectares in the previous season. For the cotton season 2011- 12, Cotton Advisory Board has estimated cotton acreage at 121 lakh hectare.

With receipt of attractive prices for their produce in cotton season 2010-11, the cotton farmers are enthused to increase acreage under cotton in the ensuring cotton season is expected to increase further. The details of acreage under cotton in past ten years are as follows :

Table

Year Acreage under cotton in lakh ha.

2000-01 85.76

2001-02 87.30

2002-03 76.67

2003-04 76.30

2004-05 87.86

2005-06 86.77

2006-07 91.44

2007-08 94.14

2008-09 94.06

2009-10 103.10

2010-11 111.61

2011-12 121.00

(Prov.)

Source : DoCD

Table ends

Acreage under Bt cultivation

Government of India has released Bt seeds for commercial cultivation in 2002-03. Bt cotton confers resistance to important insect pests of cotton. With adoption of Bt, besides increase in yield, there was a concomitant reduction in the use of insecticides due to Bt cotton, which has enabled the cotton farmers of country in increasing their income. As a result, over the years, the cotton farmers are inclined to increased usage of Bt. The details of year-wise acreage under Bt are as follows :

Table begins

Year Total area Area under Bt % of Bt to total

2002-03 76.67 0.29 -

2003-04 76.30 0.93 1%

2004-05 87.86 4.91 6%

2005-06 86.77 10.14 12%

2006-07 91.44 34.61 38%

2007-08 94.14 63.34 67%

2008-09 94.06 68.18 72%

2009-10 103.10 80.83 78%

2010-11 111.61 98.54 88%

2011-12 121.00 NA -

(Prov.)

Table ends

Cotton Production

With various Governmental measures under Mini Missions I and II of the Technology Mission on Cotton (TMC) launched by the Government of India in February 2000, by way of transfer of technology from research level to farm level, release of good quality certified seeds, improved cropping system, supervision techniques, pest management, usage of fertilizers and release of Bt seeds for commercial cultivation, the cotton production in the country since last seven years has been continuously increasing. In terms of cotton production, India is the second largest producer of cotton in the world, after China.

The details of cotton production in the country in past ten years are as follows:

Table begins

Production in lakh bales of 170 kgs

Year Production

2000-01 140.00

2001-02 158.00

2002-03 136.00

2003-04 179.00

2004-05 243.00

2005-06 241.00

2006-07 280.00

2007-08 307.00

2008-09 290.00

2009-10 295.00

2010-11 325.00

2011-12 355.00

(Prov.)

Source : Cotton Advisory Board

Table ends

Cotton Consumption

Domestic consumption of cotton fibre has witnessed sustained growth since 2003- 04 onwards due to growing demands for Indian textiles and subsequently there has been considerable expansion and modernization of textile mills. The CAB has placed cotton consumption at 281.00 lakh bales for 2011-12 season as against 253.00 lakh bales in previous year. The details of cotton consumption in the country in past ten years are as follows :

Table begins

Quantity in lakh bales of 170 kgs

Year Mill con. Small Mill Non-Mill Total

2000-01 149.36 10.97 12.70 173.03

2001-02 147.00 11.70 13.06 171.76

2002-03 142.42 11.63 14.78 168.83

2003-04 150.39 13.00 13.71 177.10

2004-05 163.98 16.57 14.48 195.03

2005-06 180.00 19.00 20.00 219.00

2006-07 194.89 21.26 15.88 232.03

2007-08 195.67 22.08 19.13 236.88

2008-09 190.00 20.00 19.00 229.00

2009-10 207.00 23.00 20.00 250.00

2010-11 236.00 17.00 253.00

2011-12 (P) 264.00 17.00 281

Source : Cotton Advisory Board

Table ends

MINIMUM SUPPORT PRICE (MSP) OPERATIONS

The Government is operating the Minimum Support Price (MSP) Scheme through the agency of Cotton Corporation of India Ltd. (CCI), a public sector enterprise, to ensure a minimum return to the farmer even in the depressed market conditions. The support prices are fixed by the Government for two basic varieties of cotton of fair average quality, recommended by the Commission for Agriculture Costs and Price (CACP). While one is the medium long staple length group of 24.5 to 25.5 mm with micronaire value of 4.3 to 5.1 of the variety F 414/H-777/J-34 and the other is the Long Staple Length group of 29.5 to 30.5 mm with micronaire value of 3.5 to 4.3 of the variety H-4 of new crop of Seed Cotton (Kapas). Based on the support price of these two basic varieties and taking into account the normal price differential and other relevant factors., the MSP for other varieties of seed cotton of fair average quality are fixed by the Textiles Commissioner.

MAN-MADE FIBRE

See graphic

The Man-Made Fibre (MMF) and yarn industry comprises fibres and filaments of both cellulosic and non-cellulosic origin, generally referred to as rayon and synthetic fibres/yarns. The man made fibres play an important role in manufacture of Textile items especially Technical Textiles. While most textiles producing countries have a consumption ratio of MMF to cotton as 60:40, in India it is still 49:59 (F.Y. 2009-10). Considering the importance of this sector, Government is promoting the MMF sector and production of such fibres and yarns has shown a rising trend during the last five years to the extent that India is second largest producer (2009) in the world.

JUTE AND JUTE TEXTILES INDUSTRY

The Jute industry occupies an important place in the national economy. It is one of the major industries in the eastern region, particularly in West Bengal. Jute, the golden fibre, meets all the standards for safe packaging in view of being a natural renewable, biodegradable and eco-friendly product.

Globally, India is the largest producer and second largest exporter of jute goods and this sector supports the livelihood of about 40 lakh farm families, and provides direct and indirect employment to 4 lakh workers. There are 79 composite Jute mills in the country. Out of the total 79 jute mills, 62 jute mills are located in West Bengal, 3 each in Bihar and Uttar Pradesh, 7 in Andhra Pradesh and one each in Assam, Orissa, Tripura and Chhattisgarh. Annually, the export of jute products ranges between 1,300-1,400 crore.

The production of raw jute varies between 100-110 lakh bales (180 kg. each), and the domestic consumption of jute goods is in the range of 13.5-14.5 lakh MT. The production of jute is concentrated in 36 districts of West Bengal, Odisha, Bihar, Assam, Meghalaya, Tripura and Andhra Pradesh. In the 2010-11 jute season (June- July), the production of raw jute is expected to reach 104.83 lakh bales (of 180 kgs each).

The Government on June 2, 2006, approved the implementation of the Jute Technology Mission (JTM) at an estimated cost of Rs.355.55 crores, of which the outlay for mini mission III and IV is Rs.38.60 and Rs.260.00 crores respectively. The Department of Agricultural Research and Education, Ministry of Agriculture, launched the Mini Mission I of the Jute Technology Mission (JTM) on November 9, 2006. The Department of Agriculture and Cooperative, Ministry of Agriculture, launched Mini Mission II of JTM on December 21, 2006. Mini Mission III and IV were launched by the Ministry of Textiles on February 6, 2007. The JTM comprises four Mini-missions:-

(i) Mini-mission I-Strengthening of Research and Development

(ii) Mini-mission II- Transfer of Technology

(iii) Mini-mission III-Development of Marketing Infrastructure

(iv) Mini-mission IV-Modernisation/Upgradation of Technology of Jute Sector and initiation of activities for promotion of Jute Diversified Products.

The cap on subsidy for Acquisition of Machinery and Plant under Jute Technology Mission has been raised to Rs.3.5 crores per mill and Rs.4 crores per mill in respect of new mills in North Eastern Region (NER). A subsidy of Rs.31 crores has been disbursed under the Scheme (corresponding to investment of Rs.155 crores) for modernization of Jute Mills.

The revival package of National Jute Manufactures Corporation (NJMC) has been approved which envisages operationalisation of three jute mills viz. Kinnison and Khardah in Kolkata (West Bengal) and Rai Bahadur Hadrut Mill (RBHM), in Katihar (Bihar). The trial runs in the three jute mills have been completed. The RBHM in Katihar has already started its production.

There is great scope in Jute Diversified Products specially Jute Geo Textiles (JGT). The Ministry of Rural Development is to construct about 1,000 km. of rural roads using Jute Geo textile and Indian Railways would be using more Jute Geo Textiles in track repair and new tracks. In addition, international project with IJSG for testing, standardization and certification of JGI has been launched.

THE SERICULTURE AND SILK TEXTILES INDUSTRY

Sericulture is a labour-intensive industry since all activities involve labour support such as cultivation of silkworm food plants, silkworms rearing, silk reeling, and other post-cocoon processes such as twisting, dyeing, weaving, printing and finishing. It provides employment to approximately 72.5 lakh persons, most of whom are small and marginal farmers. Cultivation of sericulture is being practiced regularly in contiguous districts in the traditional States of Karnataka, Andhra Pradesh, Tamil Nadu, West Bengal and J&K; in all the States of the North Eastern Region; in the tribal areas of Jharkhand, Chhatisgarh, Uttarakhand, Odisha. The silk processing industry has traditionally existed in clusters. India has the distinction of producing all the four commercially known varieties of silk, namely, Mulberry, Tasar, Eri and Muga.

Central Silk Board

Central Silk Board is a statutory body functioning under the administrative control of the Ministry of Textiles, Government of India. One of the earliest commodity boards constituted in April, 1948 under the Act of Parliament, the Central Silk Board is entrusted with the overall responsibility of developing the silk industry covering the full gaomut of sericultural activities in the country. Besides coordinating the development of sericulture industry in various States, the Board is also directly responsible for organizing sericultural research, training of sericulture personnel, basic seed production, monitoring of prices and impact of imports and exports, standardization and quality control measures etc. The CSB is also responsible for advising the Govt. on all matters concerning they development of the industry.

The programmes of Central Silk Board are broadly classified as under.

- Major Programme CSB

1. RS.&D/Transfer of Technology/Training/IT initiative

2. Seed Support & Technical Assistance/HRD

3. Catalytic Development Programme 4. Quality Certification Systems

Research & Development

For carrying out Research and Development activities, the Central Silk Board has established 3 major Research institutes for Mulberry at Mysore (Karntaka), Berhampore (West Bengal) and Pampore (Jammu & Kashmir). The Institute at Ranchi (Jharkhand) deals with Tasar, whereas, the Institute at Lahdoigarh (Assam) is looking after research and development related to Muga and Eri sericulture. Post cocoon RS.&D activities are carried out by Central Silk Technological Research Institute (CSTRI), Bangalore. The Silkworm Seed Technology Laboratory (SSTL), Bangalore (Karnataka), is engaged in research on issues relating to Silkworm Seed.

While the Central Sericultural Germplasm Resource Centre (CSGRC), Hosur (Tamil Nadu) has the responsibility of maintaining sericulture Germplasm, the Seri-Biotech Research Laboratory (SBRL), Bangalore, attends to RS.&D in frontier areas like molecular characterization of silkworm races and mulberry varieties. In order to increase productivity and quality of silk, the chain of Research Extension Centers are engaged for transfer of technologies from Research Institutes of the field. The following table indicates the increase in productivity of silk during 4 years of 11th Plan.

Table begins

Unit : Metric Tonnes

Year Mulberry Mulberry Non-MulberryTotal Raw Per Ha.

Hecterage Raw Silk Silk Productivity

Coccon Raw Silk (in kg.)

Mulberry

Raw Silk

2007-08 184928 132038 16245 2075 18320 87.84

2008-09 177943 124838 15610 2760 18370 87.73

2009-10 188773 131661 16332 3368 19690 88.82

2010-11 170314 130714 16360 4050 20410 96.06

2011-12 (P) 171697 43395 5384 783 6167 -

(upto July, 2011)

P : Provisional

Table ends

Training

The Research Institutes of the Central Silk Board provide training to the staff of the departments of Sericulture, Entrepreneurs and Stake holders of the Industry. The EDP Cell of CSB conducts Entrepreneurship Development programmes, and other related training programmes to improve the technical and managerial skills of the trainees. During 4 years of 11th Plan (upto June, 2011) a total of 16988 number of persons under different courses by the RS.&D Units and a total of 2200 persons under Entrepreneurship Development Programme were trained.

Seed Support

CSB has the responsibility for supply of basic, seed material of (both silkworm and its host food plants) required for further multiplication besides undertaking production of quality silkworm seed (F1) to supplement the efforts of the concerned state sericulture departments as a quality leader to a limited extent. Under this programme, technical assistance and field level training are also provided to the farmers by the Grainage extension centers. The CSB has a chain of Basic Seed Farms supplying basic seeds to the States. For commercial seed production with the efforts of the States in supplying commercial silkworm seed to farmers. CSB's commercial seed production involvement is about 10-12 percent of the country's current estimated production.

During the 11th Plan 20 grainages (SSPCs) of the NSSO have produced 1196.10 lakh quality dfls (upto June 2011) of different combinations. Similarly, the production of Eri, Oak Tasar, Tropical Tasar and Muga dfls during 11th Plan (up to June, 2011) has been 8.28 lakh, 6.86 lakh, 128.32 lakh and 6.84 lakh respectively.

Catalytic Development Programme (CDP)

The Catalytic Development Programme (CDP) consists of various components (about 57 in numbers) and sub-components under Mulberry, Tasar, Eri and Muga sectors. The programme is being continued and implemented as a Centrally Sponsored Scheme with certain modifications but in a package-mode during 11th Plan. The components are beneficial for both existing and new farmers for practicing sericulture. The State Departments of sericulture have to identify existing as well as new farmers and offer the components according to their requirements from out of the basket of components.

The packages under CDP covers three major areas— Seed Sector, Cocoon sector and Post cocoon sector and will be supplemented by other components of Support Services, which are common to all packages. This has been done after merger/ZBB exercise of 10th Plan Schemes. Within each package, flexibility can be built-in to cater to the specific needs of different seri-zones in the country. The main Working Group in Textiles and Jute Industry for 10th Plan constituted by the Planning Commission had in-turn constituted the Sub-Group on Sericulture, which has recommended continuation of the CDP during the 11th Plan with certain modification and some more inputs. The projections are also based on the recommendations made by the Sub-Group and the Working Group, the report of which has been submitted to the Planning Commission.

• The package under Seed sector is having components for seed production in the Public/Private sector and/or with public-private partnership in case of Mulberry sector and through support to States and also for private Graineurs in the Vanya sector.

• The package under Cocoon sector supports component for food plant development (Mulberry varieties like V-1 and Bivoltine hybrids/Double hybrids) together with the technology for a concerted effort to produce Biuvoltine silk, supply of rearing equipments including improved mountages, irrigation facilities, construction of rearing houses, supply of disinfectants, chawki rearing centre, with the essential insurance coverage for all sectors under Sericulture.

• The above packages are supplemented by other components of Support Services in nature, which are common to all packages.

Cluster Development Projects

In pursuance of the suggestion from the Planning Commission and Ministry of Textiles, Govt. of India, Central Silk Board (CSB) in close association with Departments of Sericulture has implemented Cluster Promotion Programme during 11th Plan-the main objective being promotion and development of sericulture on a sound footing in a limited geographical areas by means of transfer of latest technology in a systematic way and also through infrastructure upgradation of farmers, improvement of skills & knowledge of farmers and strict discipline in sericulture practices to improve production, productivity and quality of cocoons to support the targeted production of both mulberry and vanya silk. The programme was commenced during 2008-09 after obtaining the concurrence from the participating States.

Under the Cluster Promotion Programme, 45 model Sericulture Clusters have been organized in 16 States viz., Karnataka (7), Tamil Nadu (6), Andhra Pradesh (6), Jammu & Kashmir (4), West Bengal (3), Maharashtra (3), Orissa (2), Uttarakhand (2), Uttar Pradesh (1), Himachal Pradesh (1), Chhattisgarh (1), Assam/BTC (4), Meghalaya (1), Mizoram (1), Nagaland (1), and Manipur (2), covering Mulberry (31), Tasar (3), Oak Tasar (4), Muga (4) and Eri (3) sectors in pre-cocoon sector in close co-ordination with State Sericulture Departments. In Mulberry Sector, assistance has been provided mainly towards raising plantation, irrigation, supply of improved rearing appliances, disinfectants, support for chawkie rearing, construction of rearing houses, seri-poly clinics, insurance, beneficiary training programme, etc. In vanya sector the assistance extended for raising plantation, supply of rearing equipments/tools to seed and commercial rearers, private graineurs, construction of eri rearing houses, Farmers' Training/Study Tour, insurance support, etc.

These clusters have covered around 12846 farmers both in mulberry and vanya sectors during 11th Plan (upto July, 2011). This apart, 5 postcocoon clusters have been organized one each in the States of Tamil Nadu, West Bengal, Andhra Pradesh, Maharashtra and Assam, CSBs share of 3.83 crore has been released/sanctioned upto 2011-12.

This apart, seven mulberry clusters two each in Bihar and Himachal Pradesh, three in Kerala and one Eri cluster in Bihar have been established directly under CSB in 10th Plan and are continuing in 11th Plan (except eri culture in Bihar). While the Phase I of Cluster Development Projects in Bihar and H.P. have been completed during 2007-08, Phase II of cluster development projects for development of mulberry sericulture have been drawn for the States (i.e. Bihar-3 nos. and Himachal Pradesh-2 nos.) and the same are under implementation from 2008-09.

Application of Remote Sensing and Geographical Information System (GIS) in Sericulture

In order to map and identify additional potential areas for development of food plants for mulberry and Vanya sericulture in different states and to carry out an appraisal survey to evaluate the progress of sericulture development in few selected areas using remote sensing technology. The project is being implemented in collaboration with the NESAC, Shillong during the 11th Plan (2007-12) covering all the states, involving a total cost of 2.50 crores. Accordingly, the Central Silk Board, Ministry of Textiles, in association with North Eastern Space Application Center (NESAC), a unit of Department of Space, Government of India has taken up the project "Applications of Remote Sensing and GIS in Sericulture Development". The objectives of the Projects are :

• To map and identify the potential areas for development of food plants for mulberry and vanya sericulture in the non-traditional States on 1:50,000 scale.

• To carry out an appraisal survey to evaluate the progress of sericulture development (pre and post project) for a few selected areas from the four sericulture zones, and

• To develop and implement a network of Sericulture Information Linkage & Knowledge Systems (SILKS).

The Study Covers :

• States including NE States for -Identification of additional potential areas for development of silkworm food plants : All NER states including Sikkim (8 States), Bihar, Chhattisgarh, Himachal Pradesh, Jharkhand, Kerala Madhya Pradesh, Maharashtra, Odisha, Punjab, Uttarkhand and Uttar Pradesh.

• Selected areas/districts in the four sericulture zones, including traditional states viz., Karnataka, Andhra Pradesh, Tamil Nadu, West Bengal & Jammu & Kashmir, will be covered for appraisal survey.

• All sericulture-practicing districts covered under the project will be covered for Sericulture Information Linkage & Knowledge System (SILKS).

Special Projects

The Central Silk Board is implementing integrated sericulture development projects in different states in collaboration with the State Sericulture Departments and the NGOs. The CSB is also implementing few special SGSY projects for sericulture development by availing the funds from the Rural Development Departments. During the last 3 years, the Central Silk Board has provided financial assistance to NGOs, under centrally sponsored Catalytic development Programme (CDP) being implemented during 11th Plan.

Export Potential

The export earnings from the silk are growing steadily because of increasing demand for Indian Silk goods particularly from small markets-Asia region in addition to the traditional major markets like USA and European countries. During 11th Plan export earnings from silk goods of the country were Rs.2727.87 crores (2007-08), Rs.3178.19 crores (2008-09), Rs.2892.44 crores (2009-10) and Rs.2723.86 crores (2010-11). However, due to melt down in the global economy, sharp appreciation in the rupee vis-a-vis US$ witnessed in the year 2007-08 onwards, there was a slump in silk goods exports 18.3%, 4.8%, 13.4%, & 18.4% respectively when compared to the export of Rs.3338.35 crores at the end of 10th Plan (2006-07). Export earning for the year 2011-12 is available from the source for the month of April, 2011 only which was 163.13 crores, indicates a decrease of 12.6% (Rs.186.65 crores) over the same month of previous year.

Central Silk Board (Amendment) Act, 2006

The CSB (amendment) Act, 2006 was enacted to regulate the quality silkworm seeds and came in to force w.e.f. September, 2006. The broad objectives of the amendments are :

• To bring about the Qualitative improvement in silkworm seeds & seed cocoons to establish forward and backward linkages. The mechanism provided in the amendment ensures high quality silkworm seed used for basic seed crop rearing and also for commercial rearing of silkworms which ultimately helps in the production of good quality cocoons and silk yarn.

• To produce required quantity of quality seed.

• Seeds produced should be certified for quality and distributed to the farmers so that farmers are assured of quality.

• To develop ASR concept to constantly upgrade the quality as a part of backward linkage.

• To ensure quality production and certification, seed testing laboratories and seed Certification Centers have been proposed.

• The amendments effected are aimed to promote quality based seed & seed cocoon, free trade ensuring better and remunerative prices to the farmers, reelers, twisters and others in the silk production chain.

Silk Mark Organization of India (SMOI)

The Silk Mark Scheme was launched in India primarily to protect the silk consumers' interest. Silk in India has been facing unfair competition from man-made substitutes like viscose, polyester, nylon, etc. which is passed on to the unsuspecting consumers as pure natural silk, depriving them and the stakeholders like farmers, reeler, etc. the real value. This has been a serious problem in the Indian silk industry leading to lack of trust among consumers while buying silk.

Such unfair practices has also been affecting the Indian sericulture farmers rearers, reelers, graineurs and other stake holders who do not seem to get real value for their produce since these substitutes take the market share. The Govt. of India realising the seriousness of the issue, launched Silk Mark Scheme in June 2004 to help the consumers in identifying pure silk products. The Scheme is being implemented by the Silk Mark Organisation of India presently functioning under the Central Silk Board Ministry of Textiles, Govt. of India.

The Silk Mark Organisation of India has organised massive advertisements, awareness programmes, interactions with the various women's organizations, fashion institutes, textile research labs, consumer groups etc. During 11th Plan period till 2011-12 (upto July, 2011), more than 1300 programmes/events have been organised to crease consumer awareness. Silk Mark has reached many cities across the country. Some of these are Bangalore, Chennai, Mumbai, Pune, Hydrabad, Vijaywada, Kancheepuram, Salem, Coimbatore, Kolkata, Bhubaneshwar, Guwahati, New Delhi, Chandigarh, Varanasi, Lucknow, Srinagar, Trivandrum, Kochi etc. Extensive efforts were made for promotion of Silk Mark and consequently now, SMOI is a family of more than 1700 Members and more than 1.20 crores of Silk Mark labeled products has reached the market in the country.

As part of its efforts to protect consumers interest and for generic promotion of natural silk, the Silk Mark Organisation of India (SMO) continues to participate in various exhibitions and conducts expos/awareness programmes for consumers and trade across the country. In order to enable consumers to source pure silk products from different silk clustes of the country and also to provide a platform to authorised users to promote their exclusive silk products, the Silk Mark Organisation of India conducts a series of Silk Mark Expos in various cities across the country. During the 11th plan period, SMOI has conducted 52 Silk Mark Expos on a self sustaining basis in the cities of Bangalore, Mangalore, Mumbai, Pune, Chennai, Coimbatore, Hyderabad, Vishakapatanam, Kolkata, Bhuwaneshwar, Rourkela, Guwahati, New Delhi, Chandigarh, Lucknow, Jaipur, Kochi and Mysore.

Conducting such expos by SMOI has created an excellent platform for the weavers, designers, manufacturers, retailers etc not only to showcase their exclusive silk products but also to generate substantial business for them. A strong surveillance mechanism has also been put in place so that only 100% pure silk products are transacted during these expos which make Silk Mark Expos unique and different from other mushrooming silk expos in the country.

The Silk Mark has also made an entry into international arena by participating in major international events like Heimtextil, Silk Paradise, Tex Trends., International Handicraft Gift Fair, Australian Sourcing Fair, Namaste India etc.

The Wool and Woollen Textiles Industry

The woollen textiles industry is a rural based, export oriented industry in which the organized sector, the decentralized sector and the rural sector complement each other. This industry provides employment to 27 lakh workers in a wide spectrum of activities. The country is the sixth largest producer of wool and contributes 3 per cent to total world production. The production of indigenous raw wool was 45.0 million kgs in 2001-11. Of the total production of raw wool, 5 per cent is apparel grade, 85 per cent carpet grade, and 10% coarse grade. Domestic produce is not adequate, therefore, the industry is dependent on imported raw material. Wool is the only natural fibre in which the country is deficient.

A small quantity of specialty fibre is obtained from pashmina goats and Angora rabbits. There are 958 woolen units in the country, the majority of which are in the small scale sector. Government is implementing the Integrated Wool Improvement and Development Programme (IWIDP). Quality processing of Wool and Social Security Scheme for the growth and development of the wool and woollen industry in the country. The programme is being administered by the Central Wool Development Board (CWDB), Jodhpur, through State Government Organizations/ NGOs etc.

Decentralized Powerlooms Industry

The Decentralized Powerlooms sector is one of the most important segments of the textiles industry as it provides employment to 57 lakh workers and contributes approximately 62 per cent of total cloth production in the country. There are 22.55 lakh powerlooms in the country. The cloth output from this decentralised sector had increased from 30.63 billion sq. mtrs in 2005-06 to 37.52 billion mtrs in 2010-11.

More than 60 per cent of the fabric meant for export is sourced from powerlooms sector. The ready-made garments and home textiles sectors are heavily depended on the powerlooms sector to meet their fabric requirement. The major powerlooms cluster are at Erode, Salem, Madurai, Ichalkaranji, Solapur, Bhiwandi, Burhanpur, Bhilwara, Kishangarh, Ludhiana, Amritsar and Panipat. Powerloom sector produces a wide variety of fabrics for domestic as well as export markets such as shirting, suitings, dress materials, saree, dhoti, towels, chaddar, furnishing, shawls, blankets etc made out of cotton, blended, synthetic, silk, wool etc.

In order to overcome the problems faced by powerloom sector, Government of India has set up 44 Powerloom Service Centres (PSCs) in different clusters for promoting the development and growth of the decentralised powerloom sector to improve the technology level, skill development, design development etc. The Government has given a thrust for modernisation of the powerloom sector. The main emphasis was on Technology Upgradation Fund Scheme (TUFS). This scheme has given an impetus to powerloom sector and provided an additional option to the decentralised powerloom sector to avail 20% Margin Money Subsidy till 2012, in lieu of 5% reimbursement on investment in TUFS compatible machinery.

In addition to above, Government of India has introduced a Group Workshed Scheme for decentralised powerloom sector. The scheme aims at setting up of powerloom park with modern weaving machinery to enhance their competitiveness in the global market. Government of India has also launched a welfare scheme for powerloom workers viz. Group Insurance Scheme in association with Life Insurance Corporation of India.

Handlooms

The Handloom sector is an intangible asset of the rich cultural heritage of India. Nearly 43.31 lakh persons are engaged in the handloom weaving and its ancillary activities as per the latest Handloom Census of India (2009-10).

The all India Handloom Census (initiated in 2009-10) has successfully been completed and the final report was released on 23.12.2010. Photo identity cards (PICs) for the eligible handloom weavers and allied workers have been issued. As per Third Handloom Census there are 43.31 lakh weavers & allied workers and 23.77 lakh handlooms across the country.

The fabric production, which was witnessing a down turn, has staged a smart recovery. The sector produced over 6,903 million sq. meters of handloom cloth in 2010-11. Moreover, the export of handloom products increased by more than 6% during 2010-11.

The Finance Minister in his annual Budget Speech 2011-12 has announced the Financial Package of Rs.3,000 crores for the Handloom sector which will benefit more than 15,000 Handloom Weavers' Cooperative Societies and more than three lakh handloom weavers for cleansing the overdue loans and interest of Weavers' Cooperative Societies and for providing loan to handloom weavers at lower rate of interest. In addition to this, the reduction of import duty on silk yarn from 30% to 5% (also announced during the Budget Speech) has brought down the prices of raw silk and stabilized the prices of domestic and imported raw silk.

The Schemes of the Government of India have played an important role in support and preservation of traditional skills and to facilitate the market linkage for the benefit of the handloom weavers. Four Mega Clusters at Varanasi (UP); Sivasagar (Assam); Murshidabad (WB) and Virudhnagar (TN) have been identified for the development of 25,000 looms in these four clusters. This is addition to 20 Pilot Projects (having 5000 looms each) running successfully in major handloom states all over the country. 541 clusters (having 300-500 looms) and 1788 Group Approach Projects (having 10-100 weavers' population) has also been developed throughout the country to provide various developmental and welfare schemes to enable the handloom weavers to withstand competition from powerloom and mill sectors.

During 2010-11, sales worth Rs.410 crores has been reported in 680 events. The websites provide free access to 1250 design, trends/forecast and linkage to various other related websites on handloom development activities. Market support is also being provided in the form of Marketing Incentive @ 10% on the average sales turnover for the last three years. To protect the distinctive identify of handloom products the handloom products the Handloom Mark and Geographical indication (GI) registration has been provided to traditional handloom products from specific regions such as chanderi; Varanasi, west Bengal etc.

As a social security cover, the Health Insurance Scheme provided comprehensive health insurance cover worth Rs.15,000/- (out of which Rs.7,500/- is for OPD) to more than 16 lakh weaver families. The Life Insurance Scheme provided life insurance cover in case of death or disability to 5.27 lakh weavers. During 2010- 11, scholarship benefits of Rs.300/- per quarter per child studying in standard IX to XII have been provided to 1.55 lakh weaver's children.

Five Indian Institute of Handloom Technology (IIHTs) and 25 Weavers' Service Centres are running at Varanasi, Salem, Guwahati, Jodhpur & Bargarh. These IIHTs are conducting 3 years Diploma Course in handloom technology to provide professionally qualified manpower to the Indian Handloom Industry. National Handloom Development Corporation (NHDC), a Government of India undertaking supplies yarn to eligible handloom agencies through 750 yarn depots and also reimburse the transportation expenses involved in the supply of yarn and expenses on operating the yarn deposits @ 2.5%. During the 11th Plan, 3893.62 lakh kg. of yarn valuing Rs.3783.58 crore (upto August 2011) has been supplied to the eligible agencies under the scheme.

Garments

Fettered by archaic rules

The Times of India, Dec 19 2016

Bizarre garment rules tie down textiles cos

Surojit Gupta & Sidhartha

Did you know that your shirt may be among several products that mandatorily need a date of manufacturing? And till a few years ago, some shirts also had to mention the date of expiry to avoid “visits“ by “inspectors“. The country's archaic and often bizarre rules for garment manufacturers and retailers meant that the last vestiges of `Inspector Raj' continued for this crucial sector. Most of them, including some of the biggest names in the industry , have been grappling with laws that treat clothes in the same way that inspectors deal with packaged atta or sugar.

There are several examples to show how bizarre the rules are. In a metropolitan city , inspectors from the state's weight and measures department issued a notice to the directors of a leading garment brand as the tag did not mention the measurement in metres.

In the same city , another notice was served as the price tag on 10 out of 6,000 garments in a store did not carry the “proper retail sales price“ since the law requires pricing in two decimal points. There was another alleged violation as the customer care number should have been a landline phone and not a mobile number, which was mentioned on the price tag.

In another metro, the price instead of being “inclusive of all taxes“ was “inclusive of all taxe“ -reason enough for the state machinery to serve a notice for violation of the Legal Metrology (Package & Commodities) Rules, 2011.

As a result of the outdated rules, even for a shirt or a pair of socks, the manufacturing date is required -so mething that most buyers hardly notice when buying garments. Similarly , just writing Small, Medium or Large will not suffice since the rules require garment makers to provide the measurement in centimetres.And, writing “cm“ instead of “cms“ allows the government to hold the director of a company liable with possible imprisonment and fine. That gives inspectors enough reason to land at outlets and start serving notices. “Basically, many of them want a monthly deal,“ said a leading textiles player who did not wish to be identified, fearing harassment in several states where he has outlets.

Industry players have petitioned the government that just putting shirts in a plastic cover does not turn them into a “packaged commodity“ as the idea is to protect the fabric from dust. Similarly , clothes are not sold by weight and, therefore, it should have a different set of rules instead of applying same principles as other commodities covered by the Standards of Weights & Measures Act.

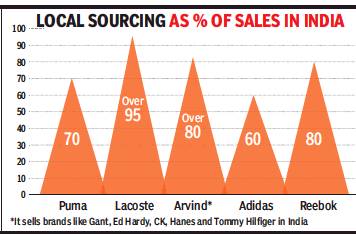

Global apparel brands

2018: High local content

From: JOHN SARKAR, Textile duty hike to have little impact on global apparel brands, August 17, 2018: The Times of India

The government’s doubling of import duty on textile products will have a marginal impact on global apparel brands as several of them have localised manufacturing.

Earlier in August 2018, the government had raised import duty on a gamut of textile products to protect domestic manufacturers and support the ‘Make-in-India’ initiative. Local manufacturing is expected to boost the demand for raw materials, including cotton, and provide a fillip to the employment sector.

“Three years ago, around 50% of our goods were sourced locally,” said Abhishek Ganguly, MD of Puma India. “We have ramped it up to 70% and are aiming for more. It’s easier to make cotton garments in India currently compared to technical clothing. In some such cases, we import the fabric and get the apparel made here.”

Certain types of technical fabrics that are used in making sportswear are still being imported. Ganguly said Puma has been approached by several local manufacturers, including Arvind and Gokaldas. “They have shown an interest in developing high-end fabrics and garments that are used in sportswear but the talks are in a nascent stage,” Ganguly added.

Textile giant Arvind, too, is accelerating its efforts to localise end-to-end manufacturing of garments for global fashion brands. “More than 80% of products of the brands that we sell here are Made-in-India, so the impact of import duty hike is going to be marginal except for some areas,” said executive director of Arvind, Kulin Lalbhai. Arvind is a supplier to companies such as Zara, H&M and Marks & Spencer.

In addition, the Ahmedabad-headquartered company plans to open plants in Gujarat, Jharkand and Andhra Pradesh in a bid to bolster its verticalisation plans and decentralise manufacturing. “China is becoming expensive in terms of labour cost. India is going to be strategic for garment manufacturing in the near future,” Lalbhai added.

Handicrafts

Handicrafts represent the rich and diverse cultural heritage of the country. Their cultural importance pertains to ensuring the preservation of heritage, traditional skills and talent. Their economic importance lies in their high employment potential, low capital investment, high value addition, and potential for export/foreign exchange earnings. The sector provides employment to an estimated 78.45 lakhs artisans during 2011-12 of which 47.42 per cent are female, 24.73 per cent belong to Scheduled Castes, and 12.38 per cent to Scheduled Tribes and 22.98 are minorities. The Government had launched the Rajiv Gandhi Shilp Swasthya Bima Yojana in March 2007 to provide health care services to the artisans family, including self, spouse and two children.

The Handicrafts sector has emerged as one of the most important foreign exchange earners for India on a sustained basis. India is the world leader in exported carpets with 26 per cent of global share. The progress in terms of product range, number of companies and value of exports has been tremendous-in 1997-98 exports of handicrafts were Rs.6457.69 crores and these reached the peak of industry ie Rs.13526.66 crores (including hand-knotted carpets) in 2010-11. The target of exports during 2011-12 has been fixed at Rs.15930.00 crores.

The Government has sanctioned 39 urban Haats across the country on the pattern of Delhi Haat to provide direct marketing outlets to artisans from rural and urban areas. The 20 Urban Haats at following locations have become operational. Jammu and Srinagar (J&K) Uchana Karnal (Haryana), Jodhpur and Jaipur (Rajasthan), Gohar Mahal, Bhopal (M.P.), Ahmedabad and Bhuj (Gujarat), Mysore (Karnataka). Tirupati (Andhra Pradesh), Bhubaneshwar, Konarak and Puri (Odisha), Agra and Varanasi (UP) and Pitampura, and INA (Delhi), Dimapur (Nagaland) and Raipur (Chhattisgarh), Mumbai (Maharashtra)

RESEARCH AND DEVELOPMENT

Textiles Research Associations (TRAs)

There are eight Textile Research Associations (TRAs) the Ahmedabad Textile Industry Research Association (ATIRA), the Bombay Textiles Industry Research Association (BTRA), the South India Textiles Industry Research Association (SITRA) and the Northern India Textiles Industry Research Association (NITRA) which carry out consultancy, testing training and research and development in cotton and cotton/ synthetic as well as cotton/natural fibre blends. The Man-made Textiles Industry Research Association, (MANTRA), and the Synthetic and Art Silk Mills Research Association (SASMIRA) work predominantly in synthetics. The Wool Research Association (WRA), and the Indira Jute Industry's Research Association (IJIRA) carry out work in wool and jute, respectively.

The Government recognizes that innovation is the key to survival in the globalized world. Continuous innovation in technology, machinery, products and processes is necessary for the Industry to fully exploit the opportunities available in the world market. To achieve the above objective, the Government during the 11th Five Year Plan period (2007-12), is adequately supporting TRAs.

Textile Committee

The Textiles Committee is a statutory body, constituted under the Textiles Committee Act 1963, under Ministry of Textiles; Government of India with an aim to ensure that quality of textiles and textile machinery for domestic and international market. The organisation works with a network of regional offices across the country and has more than five hundred technical personnel working with the committee. The committee has five major departments. They are (1) Testing Laboratories (2) Export Promotion and Quality Assurance (EP&QA) (3) Market Research and Intelligence study, GI Facilitation (4) Total Quality Management (TQM) and (5) Cluster Development Programme (CDP) (6) Integrated Skill Development Scheme (ISDS) and (7) Govt. Sponsored schemes such as (a) Assessment and Grading of Ginning and Pressing Factories (b) Handloom Mark Scheme and (c) Post GI Initiatives.

• The organisation runs the largest network of textile testing laboratories in the country and eighteen world-class laboratories in major textile centres across the country for providing testing facilities for textiles, chemicals, dyes and effluents.

• The Export Promotion and Quality Appraisal (EP&QA) Department of the Committee is rendering services to more than 32,000 exporters registered with Textiles Committee by issuing certificates or origin, classifying garments and making provision for quality appraisal.

• The Market Research Wing of the Textiles Committee collects and disseminates information released to textile consumption, production, distribution and related matters in the country for facilitating planning by industry, trade and the Government and also provides consultancy on specific requirements of the Government and Industry. Besides the above, the wing creates databases for the Industry and trade. As a part of supporting the traditional textile products for protecting their Intellectual Property Rights (IPR), the Geographical Indication registration is facilitated by the wing.

• In the post liberalisation era, the organisation has also reoriented its role from being a regulatory organisation to become a facilitator for quality Improvement in Indian textile and clothing industry. Now the Textiles Committee in collaboration with United Nations Conference on Trade and Development (UNCTAD) is implementing the project "Strategies and Preparedness for Trade and Globalisation in India for Textiles & Clothing Sector" for Trade Related Capacity Building (TRCB) of the stakeholders on emerging issues of international trade and its effect on textiles industry.

• The TQM consultancy division has been working with ISO certified quality engineers and well trained personnel to provide consultancy to the textile industry for implementation of ISO 9000, ISO 14000, SA 8000 and other quality/environmental management systems. So, far, more than 300 companies have benefited by this service of the Committee.

• The organisation is also implementing the Cluster Development Programme in the country. At present three clusters namely Shantipur in West Bengal. Trichy in Tamil Nadu and Bijnore in Uttar Pradesh are under implementation.

• The committee is also imparting training to the quality professionals under the Integrated Skill Development Scheme (ISDS). The course will facilitate supply of quality professionals to the industry after imparting training on different facets of textiles including textile testing. The project has been launched in 10 different centres of the country. The programme aims to address the shortage of trained manpower and to lap the huge employment potential of the sector. Once trained, the professionals will be called as Textiles Committee Certified Quality Professionals (TCCQP).

• The organisation is also implementing various Government sponsored schemes. The present schemes are

• The Textiles Committee is implementing the Handloom Mark Scheme as implementing agency to provide a collective identity to the handloom products that can be used for popularizing the hand woven products both in domestic and international market. The scheme also guarantees the buyer about the genuineness of the hand woven products. Besides, this would provide a distinctive name in identifying the product or he manufacturer. The Handloom Mark would, therefore, be a hallmark of powerful creative work that defines the product clarity, distinguishing it from competition and connecting it with customers. The Office of the Development Commissioner for Handlooms, Government of India is the nodal agency for the scheme.

• The organisation is also implementing the Scheme on "Assessment and Rating of Ginning and Pressing Factories" in India for enhancing quality of cotton.

HUMAN RESOURCE DEVELOPMENT (HRD)

Integrated Skill Development Scheme

The Integrated Skill Development Scheme was launched in July 2010 in the pilot mode for the 11th Five Year Plan. In all 14 proposals have been sanctioned with another 4 having been granted in principle approval. Total approved project cost of the proposals including in principle approvals is around j 433 crores with the grant component of j 322 crores targeting 4.34 lakhs trainees over a period of next five years.

Around 150 centres have become operational and more than 12000 candidates have been enrolled/trained. In the component II of the scheme dealing with projects in PPP mode, an RFP was issued and 47 proposals have been received. It is expected that projects worth j 70 crores shall be sanctioned with a grant component of j 52.50 crores targeting around 70 thousand trainees over a period of next five year.

Objectives of the Scheme:

• To address the trained manpower needs of textiles and related segments including Handicrafts, Handlooms, Sericulture, Jute. Technical Textiles etc, by developing a cohesive and integrated framework of training based on the industry needs. Addressing this need is critical for enhancing the competitiveness of the industry in the globalised economy.

• To increase the above, while simultaneously ensuring sufficient flexibility to meet the dynamic needs of these segments over a period of the next five years.

• To create a trainers' pool by conducting the advance training programmes at a cluster level employability of residents of the target areas through imparting of skills in the above segments.

• To ensure that the scheme is so designed as to cater to the wide range of skill sets required in various segments as listed.

Salient Features of the Scheme

• The Scheme would work on the basic principle of leveraging on existing resources and infrastructure as advised by the Planning Commission. Further, private sector participation would also be encouraged.

• The Scheme would target to train approximately 2.56 lakh persons during 2010-11 and 2011-12.

• It would cover all segments under the ambit of the Ministry. viz. i) Textiles and Apparel ii) Handicrafts iii) Handlooms iv) Jute v) Sericulture vi) Technical Textiles

• All facets of skill development will be covered viz. Basic Training, Skill upgradation, Advanced Training in emerging technologies. Training of Trainers, orientation towards modern technology, retraining, skill upgradation, managerial skill, entrepreneurship development etc.

• The training programme will be designed based on industry demand in different segments. The emphasis will be on measurable outcomes, wherein it will be ensured that all successful trainees are certified through an accredited agency. The training institutions supported under the scheme shall be required to enter into contract with a private partner for part funding as well as designing of the courses to be supported under this scheme.

• Private sector participation will be ensured, and outcomes will be strengthened by incentivising training where the trainees get employed/ self-employed after training is imparted.

• The average cost per trainee (for the Government) to be borne through the Scheme would be approximately j 7300/-.

• The Govt will meet 75% of the total cost of the project, and balance 25% would be met from Fee/ Industry Contribution. However. in courses/ programmes (of Component-I) where it is not feasible to organise the beneficiary contribution, the Empowered Committee shall be authorised to approve a higher level of government assistance.

National Institute of Fashion Technology (NIFT)

The National Institute of Fashion Technology was set up in 1986 as an autonomous Society in collaboration with the Fashion Technology (FIT), New York, to train professionals to meet the requirements of the textiles industry. The Institute has pioneered the evolution of fashion business education across the country through its network of fifteen (15) centres at New Delhi, Bangalore, Chennai, Ghandhinagar, Hyderabad, Kolkata, Mumbai, Rae Barli, Patna, Bhopal, Shillong, Kannur, Kangra, Bhubhaneswar and Jodhpur. NIFT will open a speciality Centre at Coimbatore very shortly. NIFT, besides conducting regular professional undergraduate and postgraduate programmes in Design, Management and Technology, also offers short duration part-time courses under its Continuing Education (CE) Programme.

The National Institute of Fashion Technology Act, 2006 came into force on July 14, 2006 and comes into effect from 1st April 2007. The Act provides statutory status to the Institute and formally recognizes its leadership in fashion technology sector, and empowers NIFT to award degrees to its students. NIFT is the first institute in the world to award degrees in fashion eduction.

Statutory Status

NIFT Act 2006 has accorded statutory status for the promotion and development of Education & Research in Fashion Technology with the President of India as the Visitor. The Act signifies public confidence in NIFT as a thought leader, with 'fashion' (defined in a much wider context) as a business strategy for value addition. NIFT is supported by the Ministry of Textiles and governed by the Board of Governors (BOG) and it Chairperson nominated under NIFT Act, 2006. The Director General is the Chief Executive Officer of the Institute with Head Office and a network of twelve Centres.

Leadership in fashion technology education

NIFT has been instrumental in bring about a paradigm shift in the perception of 'fashion' in India, with its connotation extending beyond the conventional apparel industry, to integrate with every aspect of the lifestyle industry. Fashion today encompasses popular trend or a lifestyle, specially in styles of dress and ornament or manners of behavior of the business of creating, promoting or studying styles in vogue or the designing, production and marketing of new styles of goods such as, clothing, accessories, craft and cosmetics, thus adding tremendous value to diverse industry and businesses.

Curriculum restructuring with international benchmarking

The new internationally benchmarked curriculum is aimed at providing education in a 10+2+4 pattern, consonant with global professional eduction system. Highlights of the curriculum include a common one-year foundation programme, craft experience, industry internships and a choice of intra-and inter-departmental electives, along with options for Twinning Programmes with international institutions. Students participate in international competitions, exposing them to the professional world and orienting them to the global industry adding to the country's talent pool in design, management and technology.

Cluster Development Initiatives

NIFT has made concerted efforts to mainstream the craft tradition of the country as an integral component of the curriculum of all programmes. It focuses on training, design intervention, technology upgradation, establishing market linkages and promotion. To facilitate this initiative, Rural Development Enterprise Centres at the cluster hubs and Shares Resource Technology and Support Centres at the sub-cluster level, have been established across the country. In all 10,000 artisans living below the poverty line in the States of Karnataka, Madhya Pradesh, Gujarat, Kerala and West Bengal will be benefited by this initiative.

NIFT has translated its vision of 'concern for social and human values' into a workable proposition by imparting knowledge to many NGOs strengthen their capabilities through classroom and other projects. Integration of craft cluster project into academic curriculum provides entrepreneurial experience, holistic learning, and real life care studies to students and faculty.

Technical Support

Over the years, NIFT has provided technical support and guidance to institution catering to the industry at the managerial, suppervisory, and shop floor levels as well as the institutions in the sub-continent. Over 75 Fashion Institutes, Schools, Education Boards and organizations have benefited from NIFT's expertise in developing fashion education programmes, infrastructure development, and systems management.

Governance

NIFT has commissioned Information & Communication Technology (ICT) enabled Enterprise Resource Planning (ERP) across NIFT Centres for online monitoring and evaluation of performance through Balanced Score Card linking it to the scheme of rewards and incentives.

New Initiatives

As a part of Research Initiative, NIFT has conceived two major research projects at "All India Level" namely. (i) Size India and 2) Design intelligence for Fashion Industry, two areas of critical contemporary relevance to the Fashion Industry, with Academic and Industry Collaborators. The findings of the research are expected to have far reaching impact on the fashion sensibilities of Indian population not without influencing the international fashion.

Sardar Vallabhbhai Patel International School of Textiles & Management

Sardar Vallabhbhai Patel Institute of Textiles Management set up in 2002 at Coimbatore. Tamil Nadu was upgraded into Sardar Vallabhbhai Patel International School of Textiles and Management (SVPISTM) and dedicated to the nation on July 7, 2010.

On July 7, 2010 SVPISTM entered into MoU with IGNOU which enables SVPISTM to offer certificate, diploma and degree programmes under the patronage of IGNOU for improving availability of educated and skilled manpower in the industry. Under this arrangement, MBA (Textile Management) course is offered at SVPISTM.

On 16th December 2010, SVPISTM entered into MoU with Technical University of Liberec, Czech Republic, providing for international exchange of research information, faculty, students etc. During 2010-11, MoUs have been signed with textile research associations viz., IJIRA, BTRA, SASMIRA, in the area of technical textiles.

SVPISTM won prestigious 18th Dewang Mehta Best Business Social Award (Under the category of Business School with best Industry Interface) on 24th November 2010.

2016

The Times of India, Jun 23 2016

Hemali Chhapia Delhi will send most IIT students in 2016